Products

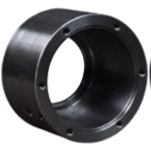

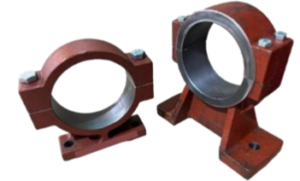

We are experts in high-precision machining of Mud Pump components, ensuring durability and performance in demanding applications. Our expertise covers:

✔ Suction Housings

✔ Bearing Housings

✔ Rotor Shafts

✔ Pump Bodies and more

With advanced precision machining and strict quality control, we deliver components with exceptional accuracy, reliability, and longevity to keep your operations running smoothly.

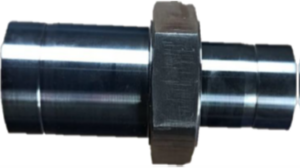

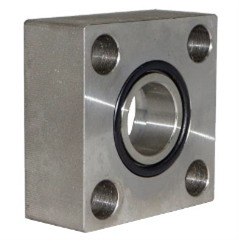

Standard & Custom Fittings for Hydraulic & Pneumatic Applications

We specializes in high-precision standard and custom fittings for hydraulic and pneumatic systems, ensuring optimal performance and reliability.

✔ Standard Fittings – Manufactured to meet global industry standards, including:

◾ ISO (International Organization for Standardization)

◾ DIN (German Standards)

◾ JIC (Joint Industry Council)

◾ SAE (Society of Automotive Engineers)

◾ BSP (British Standard Pipe)

◾ NPT (National Pipe Thread)

◾ METRIC (ISO 6149, DIN 2353)

✔ Custom Fittings – Designed and machined to exact customer specifications for unique applications.

With advanced CNC machining and stringent quality control, we deliver leak-proof, high-durability fittings tailored for critical fluid and air transfer systems.

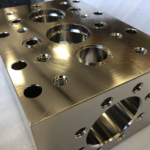

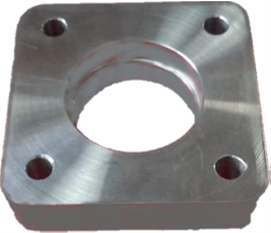

Precision-Machined Components for Diverse Applications

OMSHIV Engineering delivers high-precision machined parts from a variety of materials to meet the needs of industries requiring strength, durability, and accuracy.

✔ Castings – Precision machining of CI (Cast Iron), SG Iron, Alloy Steel, and Stainless Steel (SS) Castings for robust and complex components.

✔ Forgings – High-strength machined parts from forged materials for enhanced durability and load-bearing applications.

✔ Bar Stock Items – Custom-machined components from high-quality bar stock for precision and consistency.

With advanced precision machining and rigorous quality control, we deliver highly accurate, reliable components with superior surface finishes.